NEM 3.0 motivates home battery energy storage with growing fire risk

The CPUC NEM 3.0 will intentionally motivate home owners to use home Battery Energy Storage Systems for time shifting instead of using the grid, by paying only 8 cents/kWh to upload energy to the grid, versus 30 cents for downloading it. They are thus setting up homeowners to face a new fire threat, due to the significant hazard of Lithium ion battery storage systems.

According

to recent lessons learned on BESS fire prevention and mitigation

published by the Electrical Power Research Institute (EPRI) in June

2021, over 30 large-scale BESS globally experienced failures that

resulted in destructive fires over the past four years (Long, 2021).

These events are also tracked in the publicly accessible BESS Failure

Event Database (EPRI, 2022). Most events had in common that the lithium

ion batteries installed in the BESS where somehow driven to vent battery

gas and transition to thermal runaway, which is a process that releases

large amounts of energy. Thermal runaway is strongly associated with

exothermic chemical reactions. Under a variety of scenarios (i.e., short

circuit), the stored chemical energy is converted to thermal energy.

The typical consequence is cell rupture and the release of large amounts

of flammable and potentially toxic gases, which can lead to fire and

explosion.

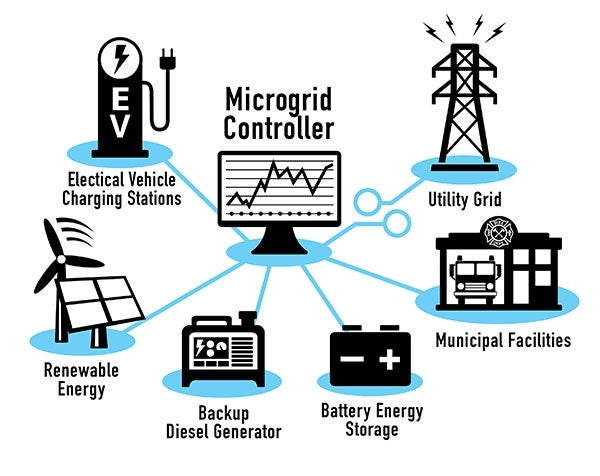

It would make a lot more sense to maintain NEM 2.0, and perform energy time shifting at neighborhood microgrids near fire stations, as San Diego is doing. Homeowners already are suffering from wildfire risk and problems getting property fire insurance. Home BESS were not widespread under the previous system, but they can be expected to be very popular under the new NEM 3.0.

CPUC Modernizes Solar Tariff To Support Reliability and Decarbonization

Under the new tariff, average residential customers who install solar are expected to save $100 a month on their electricity bill, and average residential customers who install solar paired with battery storage are expected to save at least $136 a month. With these savings on their electricity bills, new solar and solar plus battery storage customers should fully pay off their systems in just 9 years or less on average.

To support the evolution and growth of the solar industry, the decision provides extra bill credits to residential customers who adopt solar over the next five years, allowing California businesses to gradually transition from solar-only sales to solar plus battery storage sales, fostering a stronger local economy. The decision also allows residential customers, small and large businesses, nonprofits, schools, and governments to lock in their export credits for 9 years to provide certainty and predictability of bill savings.

Lithium ion battery energy storage systems (BESS) hazards

Get rights and content

Abstract

There has been an increase in the development and deployment of battery energy storage systems (BESS) in recent years. In particular, BESS using lithium-ion batteries have been prevalent, which is mainly due to their power density, performance, and economical aspects. BESS have been increasingly used in residential, commercial, industrial, and utility applications for peak shaving or grid support. As the number of installed systems is increasing, the industry has also been observing more field failures that resulted in fires and explosions. Lithium-ion batteries contain flammable electrolytes, which can create unique hazards when the battery cell becomes compromised and enters thermal runaway. The initiating event is frequently a short circuit which may be a result of overcharging, overheating, or mechanical abuse. During the exothermic reaction process (i.e., thermal runaway), large amounts of flammable and potentially toxic battery gas will be generated. The released gas largely contains hydrogen, which is highly flammable under a wide range of conditions. This may create an explosive atmosphere in the battery room or storage container. As a result, a number of the recent incidents resulted in significant consequences highlighting the difficulties on how to safely deal with the hazard. This paper identifies fire and explosion hazards that exist in commercial/industrial BESS applications and presents mitigation measures. Common threats, barriers, and consequences are conceptually shown and how they would be identified in a hazard mitigation analysis (HMA). Mitigation measures that can be implemented to reduce the risk of a fire or an explosion are discussed. The presented information is intended to provide practical information to professionals and authorities in this fairly new industry to assure that prevention and mitigation strategies can be effectively implemented and that the regulatory requirement of the HMA can be met.

Introduction

A battery energy storage system (BESS) is a type of system that uses an arrangement of batteries and other electrical equipment to store electrical energy. BESS have been increasingly used in residential, commercial, industrial, and utility applications for peak shaving or grid support. Installations vary from large scale outdoor sites, indoor sites (e.g., warehouse type buildings), as well as modular systems. Containerized systems, which are one form of a modular design, have become a popular means of integrating BESS projects efficiently. In this paper, the primary focus is placed on containerized or modular BESS.

BESS project sites can vary in size significantly ranging from about one Megawatt hour to several hundred Megawatt hours in stored energy. Due to the fast response time, lithium ion BESS can be used to stabilize the power gird, modulate grid frequency, provide emergency power or industrial scale peak shaving services reducing the cost of electricity for the end user. BESS are typically designed to output for one to 4 h. This is governed by the charge rate (C-rate). A 1C charge rate means that a fully charged battery rated at 1Ah should provide 1 A for 1 h. The same battery discharging at 0.5C provides 1 A for 30 min. Generally, lithium ion batteries perform best for fast charge rates. This makes it attractive to use BESS for short-term peak compensation and frequency control to minimize the chance of power outages. However, high powered and rapid charge cycles result in electrical transients that can generate heat quickly. This is generally true when the batteries approach a high state of charge (SOC) when charging and or a low SOC when discharging. This phenomenon may also be amplified with battery degradation. In other words, additional heat may be generated towards the end of the lifetime of the battery cell. Overheat is not beneficial to the safety, performance, and lifespan of lithium ion batteries. Hence, thermal management is of great importance. The desired range of optimal operating temperatures is often narrow and can be difficult to maintain, especially during electrical transient. In general, an optimal cooling control strategy keeps the battery cell temperature somewhere between 15 °C and 35 °C (Chen et al., 2016). This requires a reliable and well-performing cooling system that either directly cools the battery cell/modules or cools the enclosure in which the battery packs are installed. Allowing a lithium ion battery to perform outside its intended operating temperature range can have detrimental effects on safety possibly leading to fire or explosion.

To operate efficiently, grid supporting BESS (also called “in front of the meter” applications) are installed within close proximity or at sub-stations. Behind the meter BESS can be installed close to where the end-user needs the power. For example, behind the meter BESS are seen next to electric vehicle (EV) charging stations to provider a booster function or next to buildings that take advantage of the peak shaving capability and increased power resiliency. Hence, large scale BESS are often installed near additional electrical infrastructure and smaller scale BESS may be installed near buildings. In both installation cases, there are secondary aspects to the fire and explosion hazard, which deals with the protection of people and property. In the following, available technical guidance, hazard analysis methods, as well as fire and explosion hazard prevention and mitigation for BESS are discussed.

A brief review of the lithium ion battery system design and principle of operation is necessary for hazard characterization. A lithium ion battery cell is a type of rechargeable electro-chemical battery in which lithium ions move between the negative electrode through an electrolyte to the positive electrode and vice versa. Lithium-ion battery cells are a family of cells that consist of an anode (negative terminal) and a variety of different types of cathodes (positive terminal) and electrolytes. The anode and cathode serve as host for lithium ions. Lithium ions move from the anode to the cathode during discharge and are intercalated into the cathode (i.e., inserted into voids within the crystallographic structure). The ions reverse direction during charging. For a basis of understanding, a single lithium-ion cell (or battery) in a commercial/industrial application has typically an operating voltage that ranges approximately from 3 V to 4 V. Lithium ion batteries will voltages outside of this range also exist.

The anode and the cathode are separated by the so-called separator, which is a thin film made of polyolefin, for example. This film can break down if the cell overheats. The typical electrolyte is based on organic solvents which are flammable and volatile. A dissolved lithium salt provides the media for lithium-ion transport within the electrolyte. The cell can have different “form factors”, which are mainly cylindrical, prismatic or pouch. Layers of electrodes are stacked into the cell housing. Hence, the basic functional electrochemical cell contains an assembly of electrodes, electrolyte, separators, container, and terminals. A subassembly of a group of cells is called a module, which are connected either in a series and/or parallel configuration within a unit. A unit consists of a frame, rack or enclosure that consists of a functional BESS which includes the aforementioned components and subassemblies such as cells and modules, but also a Battery Management System (BMS), ventilation devices and other ancillary equipment.

BESS are installed in different forms and sizes of enclosures. This paper focusses primarily on small modular building or containerized applications as these are currently the most popular considering the number of installations. Containerized BESS are often installed in standard shipping containers that come in the ISO standard sizes ranging from 8 feet to 53 feet in length, with a width and height of approximately 8 feet each. Certainly, custom built container systems exist as well, which have sizes outside of the ISO specification. Generally, a metal container is convenient to use as a BESS enclosure. These types of enclosures are readily available, economical, and of non-combustible construction. The enclosure can be outfitted in the manufacturers’ shop and shipped to the project site as a turnkey system.

The figure below provides an example layout for an air-cooled BESS container. The overall dimensions of this container are 40 feet long, 8 feet wide, and 8.5 feet high. This design is a walk-in unit and contains two rows of battery racks. Only one row is shown as the figure is an axial slice through the center axis. The container is partitioned to include a separate auxiliary room where heating, ventilation, and air conditioning (HVAC) and communication equipment is installed. Two HVAC ducts provide cooling airflow to the batteries. There are a total of 22 battery racks, each having 12 modules. The total energy capacity of the ESS container is 4.29 MWh. This type of BESS container is then typically equipped with smoke detection, fire alarm panel, and some form of fire control and suppression system. Explosion control measures would be required for this type of system which will be explained in detail further down. The container material is steel with a thickness of 3 mm.

According to recent lessons learned on BESS fire prevention and mitigation published by the Electrical Power Research Institute (EPRI) in June 2021, over 30 large-scale BESS globally experienced failures that resulted in destructive fires over the past four years (Long, 2021). These events are also tracked in the publicly accessible BESS Failure Event Database (EPRI, 2022). Most events had in common that the lithium ion batteries installed in the BESS where somehow driven to vent battery gas and transition to thermal runaway, which is a process that releases large amounts of energy. Thermal runaway is strongly associated with exothermic chemical reactions. Under a variety of scenarios (i.e., short circuit), the stored chemical energy is converted to thermal energy. The typical consequence is cell rupture and the release of large amounts of flammable and potentially toxic gases, which can lead to fire and explosion.

A notable event that led to a shift in the industry in terms of hazard mitigation at BESS occurred on April 19, 2019, at a BESS unit owned and operated by Arizona Public Service Company. The facility, which was of modular building design (similar aspect ratios and size as of a large containerized system), experienced a thermal runaway event. The BESS was equipped with a clean agent suppression system but was not provided with deflagration venting or explosion prevention systems (i.e., the requirement for explosion control was not satisfied). The fire department responded and took no immediate action due to a lack of information concerning the system and the event. While a HAZMAT team attempted to enter the BESS to survey the scale of the event, an explosion occurred, seriously injuring the firefighters. The “McMicken” Event Technical Analysis and Recommendations report (Arizona Public Service, 2020) identified five contributing factors that led to the incident:

Internal failure in the battery cell initiated thermal runaway.

The clean agent fire suppression system was incapable of stopping thermal runaway.

The facility lacked thermal barriers between battery cells; this lack of barriers allowed the thermal runaway event to cascade to adjacent cells.

Without a means to ventilate the enclosure, the flammable off-gases from the batteries concentrated.

The emergency response plan did not include extinguishing, ventilation, or entry procedures.

Since 2017, at least 27 BESS fires were reported in South Korea. Twenty-three of the BESS fires were recorded in 2018. As a result of these events, the South Korean Ministry of Industry formed a committee to investigate the high number of fires at BESS. A five-month investigation produced a report released in June 2019. The report outlines the following key factors that contributed to the high fire frequency (MOTIE, 2019).

A lack of battery protection systems to identify and stop short circuits.

Insufficient management of the operating environment (e.g., dust, humidity, temperature swings)

Poor installation quality

Lack of integrated BESS monitoring and control systems.

Section snippets

Codes and standards

The following codes and standards are currently considered by the industry for the installation of BESS and the hazard mitigation analysis for those systems. Once a BESS exceeds 600 kWh in energy capacity, a hazard mitigation analysis (HMA) that can help identifying additional mitigation measures is typically required.

2021 International Fire Code (IFC), Chapter 12, Electric Energy Storage Systems:

- -

The 2021 edition of the International Fire Code provides prescriptive requirements and identifies

Hazard analysis

An evaluation of potential energy storage system failure modes and the safety-related consequences attributed to the failures is good practice and a requirement when industry standards are being followed. It was established above that several national and international codes and standards require that a hazard mitigation analysis (HMA) is performed. Consequences and failure modes must be evaluated that include thermal runaway condition in a single module, array, or unit, for example. Only

Prevention and mitigation measures

Prevention measures should be directed at thermal runaway. This is by far the most severe BESS failure mode as demonstrated in the introduction to the hazard mitigation analysis. If it cannot be stopped, fire and explosion are the most severe consequences.

The battery management system (BMS) provides the primary thermal runaway protection and is one of the most important barriers. This is why BESS safety standards, such as NFPA 855, require that the BMS is evaluated together with the batteries

Conclusions

This paper provided an overview of BESS fire and explosion hazards. In a time of increased development and deployment of BESS installations, it could be laid out that more incidents have been occurring. Several of these incidents experienced significant consequences in the form of fire, explosion, and first responder hospitalizations.

A technology overview was provided which was then paired with an introduction to hazard analysis. A hazard analysis in the form of an HMA is a frequent requirement

Insurance reps provide tips on reducing fire risks in battery energy storage

According to the U.S. Energy Information Administration, renewable energy sources such as solar and wind are projected to generate 44% of all power in the United States by 2050, increasing the need for battery energy storage systems (BESS). The popularity of BESS is easy to understand: It’s renewable, relatively low cost to install, resilient, efficient and quickly transfers energy from charge to discharge as needed. However, BESS do present certain risks including fire associated with battery electrolyte chemicals.

When BESS first showed up over a decade ago, they were primarily in power generation settings. Today, solar and storage installers and project developers are expanding them to commercial operations, including retail settings such as large superstores, warehouses and data centers. The technology is also expanding quickly with plans to increase utility-scale battery capacity over the coming years.

What are the risks of BESS?

The potential risks of BESS include electrical-related failures, electrocution, combustible gas release and explosion. Most BESS units are powered by lithium-ion batteries, which can experience thermal runaway, where batteries can release flammable gas and ignite when overheated or suffering a short circuit. This cascading effect triggers other nearby cells to fail and produce excessive heat and combustible gases, particularly when there is physical damage, manufacturing defects, short circuits and excessive battery overcharge.

BESS are also susceptible to mechanical and electrical breakdowns, which can render the system non-operational. They can be vulnerable to damage caused by poor handling or improper installation by solar installers or project developers.

Reducing risk of fire loss due to BESS misuse

Risk from fires can be reduced by adhering to NFPA 855 standards for all new BESS installations. These standards were released by the industry in 2020 after research by NFPA’s Property Insurance Research Group found fire hazards with lithium-ion batteries. The standards apply to the design, construction, operation maintenance and installation of BESS with the goal to reduce potential risk associated with the use of BESS.

Best practices for project developers installing BESS containers

It is important to install all new BESS containers on the exterior of critical buildings. The containers should be configured at a minimum of 25 ft from the nearest exterior wall or roof overhang and not in line with any building openings such as windows, doors and vents. Additional BESS containers should be positioned at a minimum distance of 10 ft between other battery energy storage system units/containers.

When BESS units must be placed near a critical building or adjacent storage units, installers should enhance the exterior wall to meet a 2-hour fire resistance rated assembly complete with 90-minute fire rated doors or windows. In addition, a 2-hour concrete fire wall should be provided between the unit and structure and extend past each end horizontally by half the width of the largest container and extend vertically above the height of the container by a minimum of 3 ft.

Outfit BESS with proper exhaust ventilation

In addition, installers should fit exhaust ventilation in the BESS to release off-gasses caused by a developing lithium-ion battery fire and reduce potential for excessive heat, which can lead to thermal runaway. BESS configured within small rooms, enclosures, or containers where flammable gas can exceed 25% of the lower flammable limit (LFL) should be protected with either explosion suppression or deflagration venting designed and installed within requirements of NFPA 69 Standard on Explosion Prevention Systems and NFPA 68 Standard on Explosion Protection by Deflagration Venting.

Install proper detection systems

It is also important to install continuous gas detection within the enclosure, which would activate the mechanical exhaust system upon detection of methane, benzene, ethane, ethylene, hydrogen, hydrogen sulfide and carbon monoxide, all of which are common off-gases from an early thermal runaway event.

For larger capacity units, solar power installers can integrate smoke and fire detection in accordance with NFPA 72 using very early warning smoke detection (VESDA) or radiant-type detection within the container.

Install sprinkler protection systems

Where strong water supply exists, project developers should consider protecting larger BESS capacity units with automatic fire sprinkler protection to enable adequate cooling and reduce the potential for the battery arrangements from reaching thermal runaway. Alternatively, some BESS units are now available with a pre-piped deluge sprinkler system with a connection on the exterior unit, which enables the responding fire department to connect and provide the water supply for the deluge system.

A partner with experience

While it is not easy to predict if a BESS will fail or be disrupted, it is essential for solar and storage installers to take proactive measures to help protect their company and assets. Partnering with an experienced insurance company can be beneficial to the mitigation efforts undertaken by project developers. At The Hartford, for example, risk engineering specialists know the unique risks and challenges that many businesses face. When it comes to BESS, the insurer can work with agents and brokers to help solar installers and project developers better understand the risks and help prevent issues from happening through innovative technology and specialized insurance solutions.

Stacie Prescott is Head of Energy at The Hartford. Throughout her more than 30-year career in insurance, she has gained extensive underwriting experience insuring the energy industry.

Kenneth Travers, CFPS, ARM is Technical Manager – Property and Product Specialist for The Hartford. He has more than 43 years of experience in the risk engineering field developing and delivering loss control engineering services and assessment tools for complex businesses with a focus in natural catastrophe, business impact, supply chain and fire protection engineering applications.

The information provided in these materials is intended to be general and advisory in nature. It shall not be considered legal advice. The Hartford does not warrant that the implementation of any view or recommendation contained herein will: (i) result in the elimination of any unsafe conditions at your business locations or with respect to your business operations; or (ii) be an appropriate legal or business practice. The Hartford assumes no responsibility for the control or correction of hazards or legal compliance with respect to your business practices, and the views and recommendations contained herein shall not constitute our undertaking, on your behalf or for the benefit of others, to determine or warrant that your business premises, locations or operations are safe or healthful, or are in compliance with any law, rule or regulation. Readers seeking to resolve specific safety, legal or business issues or concerns related to the information provided in these materials should consult their safety consultant, attorney or business advisors. All information and representations herein are as January 2024.

The Hartford Financial Services Group (NYSE: HIG) operates through its subsidiaries, including the underwriting company Hartford Fire insurance Company, under the brand name, The Hartford, and is headquartered in Hartford, CT. For additional details, please read The Hartford’s legal notice at www.thehartford.com.

City of San Diego Official Website

Sustainability and Mobility

Microgrids

In 2023, the City is breaking ground on the installation of microgrids at eight municipal facilities. These microgrids - standalone power grids that allow a facility or set of connected facilities to “island” or isolate from the grid and continue to operate during grid outages, relying on power stored onsite - will help the City reduce energy consumption and greenhouse gas (GHG) emissions, provide resiliency during grid outages and save on energy costs.

Partially funded by the California Energy Commission’s Advanced Solar Emergency Microgrids Grant, the project is being financed through a 25-year Energy Management Services Agreement.

Benefits

- Enables dynamic shifting of a facility’s energy load.

- Allows for energy use optimization.

- Provides clean power and community resiliency during grid outages.

- Increases resilience, meaning the ability to prepare for and adapt to changing conditions, and withstand and recover rapidly from disruptions.

- Serves similar functions as a backup diesel generator, but without the associated GHG emissions.

- Reduces energy costs - Expected savings is $6 million over 25 years!

- Supports 2022 Climate Action Plan (CAP), which sets a goal of reducing energy at municipal facilities by about 35% from a 2010 business-as-usual baseline by 2035.

- Supports Municipal Energy Strategy (MES), which furthers the CAP goal so that by 2035, all energy consumed by City facilities is from renewable sources.

The eight locations were prioritized for microgrid installation based on their ability to serve communities during grid outages, either as shelters or supply distribution centers. All are expected to be complete by summer 2023:

- Southcrest Recreation Center

- Fire Station 19 (Southcrest)

- César Chávez Community Center

- Fire Station 29 (San Ysidro)

- Dolores Magdalena Memorial Rec. Center

- Midcity Police Station

- Southeastern Police Station

- Northeastern Police Station

SDG&E UNVEILS FOUR ADVANCED MICROGRIDS TO BOOST GRID RESILIENCE AND RELIABILITY | SDGE | San Diego Gas & Electric - News Center

Video of San Diego microgrid site available here.

SAN DIEGO, Feb. 13, 2024 – San Diego Gas & Electric (SDG&E) unveiled four new microgrids featuring advanced remote operation capabilities and state-of-the-art safety technologies to help enhance grid reliability and bolster resiliency for the surrounding communities.

The four microgrid and energy storage sites, located in the communities of Clairemont, Tierra Santa, Paradise, and Boulevard, will help address surging energy demands in the San Diego region, especially during hot summer days and the peak evening hours when solar power generation typically diminishes and there is significant strain on the grid.

The ability to remotely operate microgrids offers real-time monitoring, faster response to grid events, more efficient energy storage management, and enhanced grid resilience designed to help, optimize overall performance, reliability, and sustainability. These systems utilize lithium iron phosphate (LFP) battery cells and have advanced safety and fire prevention features.

Caroline Winn, SDG&E's Chief Executive Officer, emphasized the significance of these clean energy projects in bolstering the region's resilience to the escalating challenges posed by climate change.

“Storage and microgrids are key to helping build a more resilient electric grid that can extend the availability of cleaner energy and help our communities better manage through grid emergencies like the extreme heat experienced in recent summers,” said Winn. “These microgrids will actively dispatch clean energy to the grid when needed and help improve energy resiliency for critical facilities like fire stations, schools, and cooling centers in San Diego."

Nora Vargas, San Diego County Board Supervisor, has been a long-time environmental justice advocate and emphasized the importance of equity in our road to a net zero future.

“For communities like mine that often experience outages during power emergencies, we welcome infrastructure that will help keep our lights on and our refrigerators running during difficult times,” said Chairwoman Nora Vargas. “Enhancing our power grid is an important first step in making sure all communities have access to basic resources during a crisis, especially for our local schools, fire stations, and medical centers.”

In December 2021, the California Public Utilities Commission granted the green light to SDG&E to move forward with these innovative projects. The four microgrids will operate independently or in tandem with the larger regional grid and offer a combined storage capacity of approximately 39 megawatts (MW) and 180 megawatt-hours (MWh) across four SDG&E substations.

These projects were set into motion in response to Gov. Newsom's State Emergency Proclamation in the summer of 2021. These facilities will be connected to the state energy market, allowing the California Independent System Operator (CAISO) to dispatch these resources as needed to help maintain a balanced supply and demand of energy throughout the state.

The energy storage sites are:

-

The Clairemont microgrid serves the Balboa Branch Library/Cool Zone, Fire Station 36, and local schools such as Lafayette Elementary, Sequoia Elementary, Innovation and CPMA Middle Schools and Madison High School.

-

The Elliott Microgrid will generate 10MW and has the capacity to power Fire Station 39, the Tierrasanta Public Library/Cool Zone, Tierrasanta Medical Center, Jean Farb Middle School, Canyon Hills High School, and Tierrasanta and Kumeyaay Elementary Schools.

-

The Paradise Microgrid that has the ability to power Fire Stations 51 and 32, the Southeast Division Police Department, and Bell Middle School as well as Freese, Boone and Fulton Elementary

-

The Boulevard microgrid serves the San Diego County Sheriff’s Department, Fire Station 47, Campo Reservation Fire Station, Cal Fire White Star Station, Campo Tribal Office, Campo Kumeyaay Nation Medical Center, Southern Indian Health Council Campo Clinic, the Boulevard Border Patrol Station, and the Boulevard Post Office

About SDG&E:

SDG&E is an innovative energy delivery company that provides increasingly cleaner, safe and reliable energy to better the lives of the people it serves in San Diego and southern Orange counties. The company is committed to creating a sustainable future by increasing energy delivered from low or zero-carbon sources; accelerating the adoption of electric vehicles; and investing in innovative technologies to ensure the reliable operation of the region’s infrastructure for generations to come. SDG&E is a subsidiary of Sempra (NYSE: SRE). For more information, visit SDGEnews.com or connect with SDG&E on X (formerly Twitter) (@SDGE), Instagram (@SDGE) and Facebook.

Comments

Post a Comment