Californians Could Soon Be Driving Electric Vehicles on Bumpy Roads as Gas Tax Revenue Drops | California Insider

Californians Could Soon Be Driving Electric Vehicles on Bumpy Roads as Gas Tax Revenue Drops | California Insider

Travis Gillmore

1/16/2024

Updated: 1/16/2024

EVs are much heavier than gas vehicles, and that's posing safety problems

- Nathan Bomey, author of Axios Closer

Illustration: Aïda Amer/Axios

Vehicles are adding poundage as the auto industry goes electric — and that's problematic for traffic safety, parking garages and roads.

Why it matters: Gas vehicles are slowly giving way to electric vehicles as investors, regulators and consumers clamor for more environmentally sustainable transportation.

State of play: Electric vehicles can be anywhere from hundreds to thousands of pounds heavier than similarly sized gas vehicles because EV batteries are so much heavier than engines.

- For example, the 2023 GMC Hummer EV, a full-size pickup, weighs more than 9,000 pounds, sporting a 2,900-pound battery. In comparison, the 2023 GMC Sierra, also a full-size pickup, weighs less than 6,000 pounds, according to Kelley Blue Book.

- The average weight of U.S. vehicles has already increased from about 3,400 pounds to 4,300 pounds over the last 30 years as Americans have ditched passenger cars for pickups and SUVs, according to Evercore ISI analysts.

Threat level: Safety watchdogs are raising concerns after the recent deadly collapse of a parking garage in New York City called attention to the challenge of creaking infrastructure.

- Traffic safety is particularly concerning. In crashes, the "baseline fatality probability" increases 47% for every 1,000 additional pounds in the vehicle — and the fatality risk is even higher if the striking vehicle is a light truck (SUV, pickup truck, or minivan), according to a 2011 study published by the National Bureau of Economic Research.

- "Since we’re seeing pedestrian and roadway fatalities at record levels, the introduction of more weight into crashes via EVs will complicate any attempts to reduce the ongoing fatality crisis that has showed no signs of abating," Center for Auto Safety acting executive director Michael Brooks tells Axios in an email.

Flashback: In a speech in January, National Transportation Safety Board chair Jennifer Homendy praised the effort to reduce carbon emissions by switching to EVs but warned of the "unintended consequences" being "more death on our roads," the AP reported.

- While the Manhattan parking garage collapse in early April was not blamed on EVs, the disaster nonetheless underscored an issue of growing concern: whether aging roads and old garages can handle all the extra weight.

- Less than two weeks before the collapse, a British Parking Association official recommended that parking structures integrate higher load-bearing weights amid concerns about more EVs, the Telegraph reported.

The big question: Can automakers make batteries more energy-efficient so that they weigh less yet still pack a powerful punch?

- "Unless we see incredibly rapid advances in battery design and vehicle designs, and taking smart steps like using battery energy density gains to save weight rather than extend range, or opening the doors to battery swapping, we are likely to see many additional deaths and injuries attributable solely to the added weight of EV batteries," Brooks says.

EVs cause twice the road damage of petrol vehicles, study reveals - Energy Live News

Electric vehicles (EVs) cause twice as much stress on roads compared to petrol vehicles, potentially worsening the pothole crisis in the UK, according to a study.

The research conducted by data journalists at The Telegraph revealed that the average EV exerts 2.24 times more stress on roads compared to a similar petrol vehicle and 1.95 times more stress than a diesel vehicle.

The impact is even bigger with larger EVs, which can lead to up to 2.32 times more damage to road infrastructure, according to the report.

In an analysis, 15 popular EVs were compared to their petrol counterparts, revealing an average weight difference of 312 kilograms.

The increased weight of EVs can be primarily attributed to their heavy batteries, which can weigh up to 500 kilograms.

Scientists note that this heightened stress on roads results in the increased movement of asphalt, leading to the formation of small cracks that can eventually develop into problematic potholes.

A previous report by the Asphalt Industry Alliance estimated that this cost could mean that nearly £61,700 needed to be spent for every mile of a local road in England and Wales.

Electric Vehicles And The Impact On Infrastructure

The hidden cost of road maintenance due to the increased weight of battery and hydrogen trucks and buses—a perspective

Introduction

Decarbonisation of energy used in road transport will be essential for the world to meet the necessary reductions in emissions. The two currently commercially available technological solutions for road vehicles are Battery Electric Vehicles (BEV) and Hydrogen Fuel Cell Electric Vehicles (HFCEV) (Robinius et al. 2018). At present, HFCEV vehicles are in their infancy, while BEVs are more established. However, in the UK, Zero Emission Vehicles (ZEV) of any type have not yet made significant inroads into the hydrocarbon fuelled internal combustion engine (ICE) fleet with less than 1% of the vehicle fleet and about 4.3% of new vehicle sales in 2020 (UK Government 2021a; Scottish Government 2020b).

HFCEV are typically slightly (1–2%) heavier than ICE vehicles; BEVs are usually significantly heavier (10–30%) due to the high weight of batteries (Lombardi et al. 2020). In this paper we apply existing knowledge of the relationship between vehicle weight and road wear to consider the impact of the heavier ZEVs. We do this by assessing the road wear due to the main vehicle classes at present and in the future scenarios of (1) all battery vehicles; (2) all hydrogen vehicles; (3) a combination, and comparing the overall results. A significant increase in wear would lead to a combination of increased maintenance costs, increased particulate emisions, and potentially the need to construct new roads to a higher standard.

We select Scotland as an area of analysis. This allows analysis of a fairly homogenous road construction and vehicle standard (Low et al. 2020). This is also connected with the Scottish Government’s commitment to unusually demanding targets for early decarbonisation, with a ban on new hydrocarbon car & LGV sales, and an all-sector emissions reduction of 75% from 1990 levels, to be achieved by 2030, followed by net zero emissions by 2045 (Scottish Government 2019), and also with the Scottish Government’s recent announcement of substantial investment in the hydrogen economy (Scottish Government 2020a).

This approach can be applied to other locations, subject to local factors, such as (i) existing road quality and construction standards, (ii) typical vehicle weight, numbers and construction & use regulations, and (iii) an assessment of the local applicability of the method of road wear assessment used (Rhodes 1983).

Context and Literature

There have been several relevant studies investigating the connection between vehicle weight and road wear, starting with seminal work by the American Association of Highway and Transportation Officials (AASHO) in the 1950s (AASHO 1962). This was further developed in the UK by Rhodes (Rhodes 1983) and the Transport Research laboratory (Addis and Whitmarsh 1981), and re-examined by Martin in 2002 with a focus on Australian roads of similar construction (Martin 2002), confirming the relationship first developed.

Nilsson, Svensson and Haraldson (Nilsson et al. 2020) assess the economic impact and life between major restorations of road surfaces subject to different types of loading. However, their results also find additional surface wear due to smaller vehicles. They attribute this to the use of studded snow tyres in their study area, Sweden, which are not used in Scotland.

Gustafsson (Gustafsson 2018), Denby, Kupiainen and Gustafson (Denby et al. 2018) and Stafoggia and Faustini (Stafoggia and Faustini 2018) review the impact and measurement of road wear emissions on public health, within Non-Exhaust Emissions: an Urban Air Quality Problem for Public Health; Impact and Mitigation Measures (Fulvio 2018).

This all contributes to the established and widely used principle that relates vehicle axle load to road wear in the 4th power. This is described in more detail in the Method section below.

Lombardi, Tribioli, Guandalini and Iora (Lombardi et al. 2020) examine the impact of different drivetrain types, including HFCEV and BEV on the weights of a range of vehicles, as part of their analysis into efficiency.

As the world moves into a transition to zero emissions, new vehicles will require different zero emission drivetrains. At present, available options are either BEV or HFCEV (Robinius et al. 2018). Both of these are heavier overall, with current technology, than existing hydrocarbon ICE drivetrains (Lombardi et al. 2020). Additional road wear is considered in a number of works in the context of particulate emissions (Matthias et al. 2020; Beddows and Harrison 2021), or in BEV specific road design (Börjesson et al. 2021).

Here, then, we take the established relationship between axle load and road wear and apply it to the increased weight of vehicles arising from replacing an existing national vehicle fleet with ZEVs, to arrive at the scale of the increased wear on existing roads, and hence future maintance cost.

The novelty in this paper is that this appears to be the first quantified application of the long-understood relationship between vehicle axle load and road wear to the problem of the additional weight of zero emissions vehicles. This leads to an approximate quantification of the additional cost of road maintenance as the vehicle fleet transitions to zero emissions vehicles, filling that gap in published knowledge. We introduce the new terms Road Wear Potential (RWP) of an individual vehicle, and the Road Wear Impact Factor (RWIF) which reflects the total annual wear caused by a vehicle fleet.

Hypothesis

There will be significant and quantifiable additional costs of road maintenance due to the increased weight of ZEVs over ICE vehicles. This will be markedly greater for BEVs than for HFCEVs.

Method

Rhodes (RHODES 1983) (and many others) describes the 4th power relationship between road wear and axle load, developed from the experimental work on the subject by the AASHO in the 1950s (AASHO 1962). Rhodes introduces the concept of using a Standard Axle as a way of comparing the impact of various vehicle types. The Standard Axle is taken as a single axle imposing a total load of 80kN (equivalent to 8 tonnes); the wear relative to such an axle can be readily calculated using the 4th power to give a number of effective standard axles per actual axle. We express this mathematically in Eq. 1 below.

(1)

This approach allows an assessment of cumulative impact of vehicles of different classes, and is used in other studies into road wear (Nilsson et al. 2020). As road wear is very tightly controlled by axle load, it becomes apparent that larger vehicles such as HGVs and buses will have a much greater impact than cars, relative to the vehicle weight.

Other researchers have developed different relationships—for example the UK Transport and Roads Research Laboratory produced a range of exponential powers between 2.4 and 6.6 depending on a number of factors including existing road condition and construction standard (Addis and Whitmarsh 1981). Johnsson derives a range of powers for Swedish roads between 1.2 and 8.5 (Johnsson 2004). However, for the purpose of this preliminary assessment of the road wear impact by future vehicles, we consider the single 4th power of axle weight to be adequate; this is currently used in UK and many other countries’ highways design and maintenance (UK Government 2021b).

Based on this established relationship, we introduce the terms Road Wear Potential (RWP) of an individual vehicle, and the Road Wear Impact Factor (RWIF), reflecting the total annual wear caused, which could apply to each vehicle class, sub-class, or national fleet.

The RWP reflects the potential of a vehicle to wear out the road, without considering the extent to which it is used. It depends on the weight of the vehicle and the number of axles it uses, and uses the above 4th power relationship to determine the number of effective standard axles per vehicle. We assume for these purposes that each axle in a vehicle carries an equal load. In practice this will not be the case; we examine the effect of this in the Sensitivities section.

(2)

The RWIF for each class (or sub-class) is based on the Road Wear Potential of a typical vehicle of a given class, multiplied by the average distance such a vehicle drives and by the number of vehicles in each class. This gives an overall value for comparison of the road wear associated with an entire vehicle class over the course of a year.

(3)

The Class Road Wear Impact Factors are then summed to create an overall RWIF for each scenario.

The inputs and data sources are as follows:

-

The number of vehicles in each standard vehicle class (buses & coaches, cars, motorcycles, HGV and LGV.1) (Scottish Government 2020b)

-

The typical weight, or range of weights, or fuel-based sub-classes, of ICE vehicles in each class (Scottish Government 2020b).

-

The likely change in weight due to a similar vehicle having HFCEV or BEV type fuelling and drive systems (see below for derivation).

-

The average annual distance travelled per vehicle by class, in km (UK Government Department of Transport 2019).

-

We assume that the wear and tear is directly related to the use made of the roads, i.e. the number, class and weight of vehicles using the roads, and not significantly connected to seasonal, weather and simple aging related impacts alone (Nilsson et al. 2020).

-

We use the standard UK government vehicle classes of cars, motorcycles, Light Goods Vehicles (LGV), Heavy Goods Vehicles (HGV),Footnote 1 and Buses & Coaches. HGVs are further divided into ten weight-based sub-classes, while cars and LGVs are divided into fuel based, that is petrol (gasoline) and diesel (the number of BEVs is still small enough to be insignificant) sub-classes.

To estimate the applicable vehicle weight, or reference weight, for ZEVs, we make an initial assessment of the increase in vehicle weight due to the two new fuel types, and derive simple formulas that fit data previously identified by Lombardi et al. (Lombardi et al. 2020) and vehicle manufacturers (Mercedes Benz UK 2019).

We calculate the RWP and RWIF for all classes and sub-classes, and hence the nationwide RWIF, for four scenarios:

-

Current situation, vehicle fleet overwhelmingly dominated by ICE vehicles.

-

All BEV—all vehicles replaced in the same numbers and load carrying capacity with BEVs.

-

All HFCEV—all vehicles replaced in the same numbers and load carrying capacity with HFCEVs.

-

Like for Like—all current diesel vehicles replaced by HFCEVs, and all current petrol vehicles replaced by BEVs.

Results

Initial assessment of vehicle weight and other inputs

Based on Lombardi et al. (Lombardi et al. 2020) for larger vehicles (3500 kg and over), and manufacturers’ published data for cars (Mercedes Benz UK 2019), we identify the following equivalent vehicle weights for vehicles of the same carrying capacity:

To get a suitable equivalence from manufacturers’ data, it is necessary to identify almost identical vehicles made with different fuel types. The only car commercially available both as an HFCEV and as an ICE vehicle is the Mercedes-Benz GLC (now ceased production), which is a medium-large SUV. The HFCEV version has a larger battery than is usual for an HFCEV (13.5kWh instead of around 1.6kWh (Hyundai UK 2020)), and can be used as a plug in hybrid. It is also available as a BEV (called the EQ-C, with some styling differences)(Mercedes Benz, Mercedes Benz UK 2022). Other vehicles exist as both BEV and ICE, but not HFCEV. For the purposes of consistency in this table, we use the Mercedes-Benz GLC / EQ-C for both ZEV types. We adjust the weight of the GLC Fuel Cell down by 95 kg to reflect the typical extra weight of the larger Li-Ion battery (Jung et al. 2018), to create a more relevant entry for this table.

From this table, we derive a simple relationship between the weight of a BEV and an ICE vehicle of the same carrying capacity based on the trend line function in Microsoft Excel, as follows:

(4)

and between an HFCEV and an ICE vehicle:

(5)

Both of these formulas match Table 1 data well, with a very close R2 value of at least 0.9999.

Given that the lowest data point in the original table still represents a large car, it will be necessary to extrapolate the formula slightly to get a vehicle weight more representative of a smaller one; it may be unrepresentative of motorcycles. However, as it turns out, the RWIF of cars and motorcycles is so low that this immaterial (see below).

For each class or sub-class, we have to estimate a reference vehicle weight. The key factor affecting this for large vehicles is the proportion of time the vehicles run empty or lightly loaded. This will obviously happen some of the time, with a significant change in weight. Vehicle operators will clearly try to maximise the load in their vehicles, so the actual average weight can be expected to be higher than, for example, a mid-point between empty and full. We expect that buses will run for a higher proportion of the time empty or lightly loaded, as they will be sized for peak demand. However, due to the 4th power relationship described above, the heavier loading will have a proportionately greater impact on road wear.

As a working assumption, we take the reference vehicle weight as the midpoint of the applicable weight range. We examine the implications of inaccuracies in the Sensitivities section below.

The annual distance travelled by each vehicle is taken as the average for the class or sub-class from UK government statistics. There are cases where this data is only available for a group of sub-classes (e.g. all 2- or 3- axle rigid chassis HGVs)—in this case we take the average for all relevant sub-classes. This is also examined in Sensitivities, below.

For some sub-classes of HGV, the regulated maximum weight was exceeded when the modelled ZEV vehicle weight was calculated, as seen in Table 1. In these circumstances, we assume that the maximum weight will not be exceeded, but that instead the affected vehicles will be used for additional trips to reach the same aggregate carrying capacity. We explore the effect of this further in Sensitivities, below.

Road wear potential per vehicle

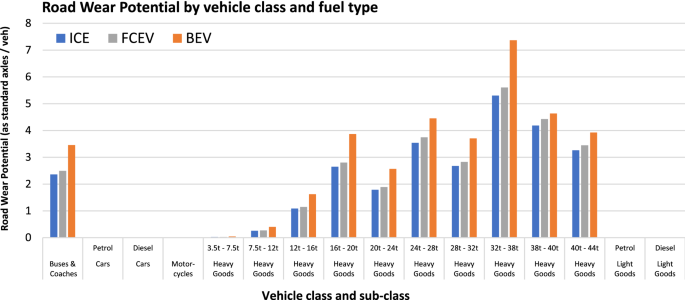

We examined the wear potential associated with individual vehicles. Figure 1 below shows the relationship between vehicle weight and Road Wear Impact Factor, taken as the number of standard axles per vehicle. This shows the RWP of a vehicle in each sub-class based on its weight and number of axles, for the three fuel types under consideration.

Road Wear Potential (RWP) per vehicle, sorted by vehicle sub-class, comparing ICE, BEV and HFCEV. RWP is the number of standard axles per axle, multiplied by the number of axles on the vehicle. Vehicles under 7.5t have negligible RWP in this context

We can see from Fig. 1, the wear potential of a larger vehicle is overwhelmingly greater than that of a smaller one, due to the 4th power law exponentially increasing the effect of greater axle load. We also see a significant increase in wear potential for a relatively small increase in vehicle weight in large vehicles, for the same reason. The mitigating effect of additional axles is also clear – the reduced number of effective standard axles per actual axle more than offsets the increased number of axles, hence the total RWP decreases for vehicles where the axle count increases. This happens at the 16-20t category, where the axle count increases to 3, at 28-32t where it increases to 4, at 38–40t which requires 5 axles, and 40–44t requiring 6 axles.

Road wear impact factor

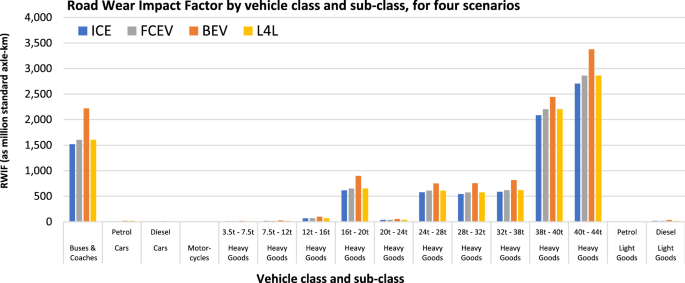

Next, we develop this into the assessment of the Road Wear Impact Factor by Class and overall, for the four scenarios under consideration. Multiplying each vehicle’s Road Wear Potential by the number of vehicles in the class and the average distance driven each year (UK Government Department of Transport 2019) produces the total Road Wear Impact Factor for each class. This produces Road Wear Impact Factors as shown in Fig. 2 below.

Class / Sub-class Road Wear Impact Factor, comparing the present and future scenarios. Road Wear Impact Factor is the Road Wear Potential multiplied by the number of vehicles in each class or sub-class and by the average annual distance travelled. Vehicle classes with a typical vehicle weight below 12t have negligible RWIF on a national scale

Clearly the overall RWIF is overwhelmingly due to the largest vehicles in use, even though they don’t have the highest RWP. This reflects the greater use made of the largest vehicles—there are more 40–44t HGVs than any other category of HGV other than the smallest 3.5–7.5t vehicles, which has about 20% more; also a typical 44t vehicle covers well over twice the annual distance of a 7.5t one. Due to the much smaller RWP, vehicles below 12t have a negligible impact on national RWIF with any fuel type.

The impact of ZEV technology in larger vehicles can be clearly seen, with BEV having a substantially greater impact than HFCEV. A table with a detailed breakdown of the calculations and results is presented in the Appendix.

Sensitivities

We considered the sensitivity of the results to different ways of estimating the input simplifications:

-

Reference weight estimate.

-

Varied load distribution, other than equal on each axle;

-

Using HGV subcategories based on axle number rather than tax bracket.

Reference weight estimate

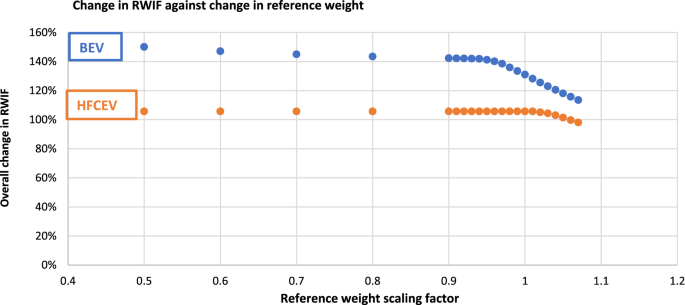

We initially assumed a reference weight at the midpoint between the top and bottom of each tax class. However, the reference weight, or typical effective weight, could be significantly different for HGVs, due to the potential for different loading and use patterns. We varied the originally estimated reference weight by scaling factors ranging from 0.5 to 1.07. Beyond 1.07, the ICE reference weight began to exceed the allowable weight in each category, particularly the heaviest, therefore a higher factor than this was clearly unrealistic.

We then used the same method to assess the overall RWIF for a range of scaling factors. We continued to use the principle that if the allowable weight for a particular axle configuration were exceeded, the weight would be held at the maximum allowable, and the distance travelled for vehicles in that sub-class would increase to provide the same gross annual carrying capacity. The result from this assessment is shown in Fig. 3:

Change in overall fleet RWIF as a consequence of change in modelled ICE reference weight. Where allowable vehicle weight is exceeded, modelled distance travelled per vehicle is increased

The final output, the change in RWIF with different fuels, is assessed as the ratio between the old and the new rather than a meaningful absolute value, so a change to both produces a similar result for most of the range. The change in RWIF decreases at higher scaling factors because increasing the distance travelled has a smaller impact than increasing vehicle weight due to the 4th power relationship, so this becomes significant at higher load scaling factors. On this basis, we describe the change in overall RWIF due to a fully BEV fleet as 20–40%, and for a fully HFCEV and Like for Like fleet as 6%.

Unequal loading

To assess the effect of unequal load distribution, we considered the effect of one axle carrying a percentage more than all the other axles, which were set as equal. An unevenly distributed load would result in a higher RWP than an evenly distributed one. However, when the same proportion of uneven-ness is applied to current and future cases, the relative increase in RWP and RWIF is unchanged. Ensuring that loads are more evenly distributed in ZEVs than at present would be a way of mitigating the increased RWP, but that analysis is beyond the scope of this paper.

Different HGV subclasses

Data is available for HGV numbers and usage based on weight-related tax bracket or on number of axles, which is also related to maximum weight. Using tax brackets gives a finer division of data; using the axle number gives a better match to the effects between sub-classes and permitted vehicle weights. Our main approach has been to use the former. Here, we re-run the analysis on the basis of axle numbers, for comparison.

However, again because the treatment is the same for ICE and ZEV, the effect on the overall result is minimal. Results are presented in Table 2.

We consider this effect to be insignificant.

Conclusion and discussion

We introduced the hypothesis “There will be significant and quantifiable additional costs of road maintenance due to the increased weight of ZEVs over ICE vehicles. This will be markedly greater for BEVs than for HFCEVs.”

We find that this partially correct—in the case of the largest vehicles, that is buses and heavy good vehicles, the hypothesis is shown to be true. However, in the case of smaller vehicles such as cars, light goods vehicles and motorcycles, it is unlikely that there will be a significant difference.

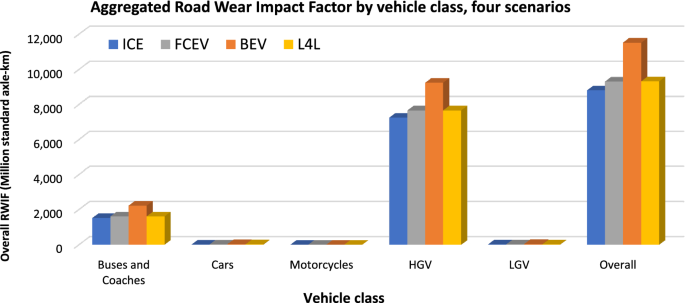

A complete conversion of the existing vehicle fleet to BEV would be likely to increase annual road wear in Scotland by around 20–40%, with a modelled base case value of 31.0%. Conversely, the same conversion to HFCEV would increase road wear by around 6% (Fig. 4). The combined, or “Like for Like” future fleet, where existing diesel vehicles are replaced by HFCEV and existing petrol vehicles are replaced by BEV, would also lead to increased road wear of around 6%.

Overall Road Wear Impact Factors, grouped by class. Subclass values have been combined to produce the overall class values

We can see from Fig. 2 above that in each scenario, the Road Wear Impact Factor is dominated by the relatively small number of HGVs, 37,000 vehicles out of a total vehicle fleet of approximately 3 million, which contribute around 87% of the Road Wear Impact Factor. The 14,000 buses and coaches are also significant, contributing around 12%. The Road Wear Impact Factors due to cars, light goods vehicles and motorcycles are insignificant, contributing in total less than 1% of the Road Wear Impact Factor in all scenarios. This will not be news to highways engineers, but needs to be understood in the energy sector. HGVs and Buses & Coaches would be HFCEVs in both the all-HFCEV and the Like for Like scenarios; as those are the vehicles overwhelmingly responsible for road wear, this leads to the Road Wear Impact Factors being effectively identical for both of these scenarios.

This effect could possibly be mitigated in the future by the introduction of lighter-weight battery technology. This is, however, speculative—while such batteries are being researched, they are not yet commercially available (Ye and Li 2021). It might also be possible to re-engineer the basic vehicle to be lighter by using lighter materials or construction methods, although these would be equally applicable to other fuel types. Also, if “e-roads”—which charge vehicles as they drive—became ubiquitous, the need for large and heavy batteries might be reduced (Coban et al. 2022).

A further mitigating effect, requiring no new technology, would be to increase the required number of axles on large vehicles – due to the 4th power effect, the reduction in wear per axle would outweigh the extra wear due to the additional axles. This would, however, increase the vehicle manufacturing costs and fuel consumption (Johnsson 2004).

The all-BEV scenario represents an increase in road wear of about 31% from the present situation; all HFCEV and Like For Like both represent an increase of about 6%—that they are almost identical reflects the dominance of diesel in large vehicles at present.

It would also be important to design vehicles such that the additional weight of batteries is evenly distributed across all axles – this would prevent an imbalanced load creating significant extra wear. This could, however, force a change in operating practice for articulated HGVs, as some of the batteries might have to be installed in the trailer unit.

It should be noted that this study considers the impact on the road network as a whole, and takes account of the relative position of present and future requirements. It is likely that specific areas, especially where the existing road has deteriorated or is of lower initial quality, that the impact will be different and smaller vehicles might become significant. Future study, including more localised analysis, might be necessary to better understand local effects. Future study would also be useful to better understand the benefit of the mitigating factors outlined above.

In Scotland, responsibility for road maintenance is shared between the Scottish Government for trunk (primary) roads, and local authorities for the much greater network of all other roads from large A-class roads through to urban access; these bodies would bear the costs related to this additional road wear. The most recent Audit Scotland report into road maintenance expenditure refers to 2015 (Audit Scotland 2016), showing the required road maintenance expenditure to maintain the existing condition. This is set out in Table 3, converted to 2021 values (Bank of England 2022), along with the additional expenditure required to provide for ZEVs in the future:

This shows the additional road maintenance expenditure in Scotland required to maintain existing condition would need to increase by around £164 M per year if all large vehicles transitioned to battery electricity. Conversely, if all large vehicles transition to hydrogen fuel cells, then an additional £31 M would be required.

It has been reported that current levels of road maintenance are inadequate at present to sustain existing road quality (Williams 2019, Audit Scotland 2016). If this is still the case, the greater demands made of the roads in the future that we outline here can be expected to lead to an even faster deterioration (Addis and Whitmarsh 1981). However, we do not assess that impact in this paper.

These additional costs, and the consequence of the additional emissions, should be included when planning the support of different fuel types on a national fleet. The fuel choice of cars, light goods vehicles and motorcycles will make little difference to road wear. However, with more HFCEV buses & coaches and heavy goods vehicles, the overall road maintenance cost will be substantially lower than with those vehicles as BEVs; it will require only a relatively small increase over the current ICE vehicle situation.

Concrete roads needed to counteract damaging impact of electric vehicles

Date: Tue 27 Jun 2023

New data shows that pothole damage from electric cars is twice than that of petrol vehicles. Asphalt road surfaces are unable to cope with the additional weight. If electric vehicles are the future, then a more robust road surface is required warns Britpave, the infrastructure industry association.

Electric cars can weigh up to two tons because of the heavy batteries. Analysis by the Daily Telegraph found that the average electric car more than doubles the wear on road surfaces which, in turn, could result in more potholes.

The average electric car puts 2.24 times more stress on roads than its petrol equivalent, and 1.95 more than diesel. Larger electric vehicles weighing over 2,000kg (2 tons) cause the most damage, with 2.32 times more wear applied to roads. Such stress on roads causes greater movement of asphalt road surface, which can create small cracks. If these are not fixed, then they can expand and eventually develop into potholes.

The Telegraph used analysis, led by the University of Leeds, which assessed the weights of 15 popular electric car models alongside their petrol equivalents. Researchers divided the models by size, including small electric cars weighing over 1,000kg, such as the BMW Mini Cooper SE 3 Door and Peugeot e208, medium models over 1,500kg such as the Ford Focus Electric and Vauxhall Corsa-e, and larger vehicles including the Jaguar I- pace EV and Audi e-tron 50 Quattro. They found that the electric vehicles were on average 312kg heavier than similar petrol versions. This is because they must carry heavy batteries, which can weigh up to 500kg.

The UK is suffering from a pothole crisis, with half as many filled last year compared to a decade ago and with an estimated £12 billion necessary to repair them. Heavy electric cars could exacerbate the problem particularly on residential and rural roads which, unlike motorways, are not constructed to withstand such heavy loads.

“Concrete roads offer a stronger road surface that offer greater long-term performance with minimum maintenance requirements than asphalt,” said Joe Quirke, Britpave chairman. “Furthermore, concrete eroads offer a charging solution that can overcome the lack of charging points.”

Concrete eRoads allow vehicle batteries to be charged inductively via wireless systems using magnetic coils embedded in the road surface that feed an electric charge to magnetic coils fitted on a vehicle’s undercarriage and so charge the battery.

“The long-term strength and performance of concrete makes well-suited for such roads as they do not need regular maintenance and in hot summers do not melt unlike asphalt roads. Road surface melting could dislodge and compromise the embedded coils,” explained Quirke.

Quirke pointed other developments for concrete eRoads which involved making the road itself conductive: “In Australia, Talga Resources are mixing graphene into concrete to make the road conductive. Whilst in Germany, Magment – concrete containing magnetic ferrite particles – is being developed for road construction.”

He continued: “The road network needs a surface solution that can help realise the potential for electric vehicles. Concrete eroads that are strong enough to withstand the additional weight of electric cars plus can charge them as they pass over offer that solution.”

Comments

Post a Comment